Efficient procurement processes are essential for the smooth operation of businesses. At the heart of these processes lies the Purchase Order (PO), a crucial document that serves as a contractual agreement between a buyer and a seller.

In this comprehensive guide, we will delve into the fundamentals of purchase orders, their key components, lifecycle in logistics, common formats, and best practices for effective management.

| Fulfill Orders with High Efficiency Achieve high efficiency in order fulfillment by optimizing purchase order processes with Detrack. Create an Account Today |

What is a Purchase Order (PO)?

A Purchase Order (PO) is a formal document issued by a buyer to a seller, delineating the specifics of a commercial transaction. It is a contractual agreement outlining the terms and conditions under which goods or services will be provided.

This document typically includes essential details such as a unique tracking PO number, buyer and seller identification, item descriptions, quantities, prices, and delivery dates.

Additionally, payment terms, including any discounts or penalties, are specified within the PO.

Once the seller receives the PO and agrees to its terms, they acknowledge it and fulfill the order. The PO is crucial in streamlining procurement processes, ensuring clarity and mutual understanding between the parties involved, and serving as a reference for record-keeping and auditing purposes.

10 Key Components of a Purchase Order

- Purchase Order Number

This unique alphanumeric identifier is a crucial reference point throughout the procurement process. It helps track orders, facilitates buyer and vendor communication, and streamlines inventory management.

- Vendor Information

The vendor information section of a purchase order provides essential details about the supplier or vendor involved in the transaction. This typically includes the vendor’s legal name, address, contact information, and sometimes tax identification numbers or vendor codes.

- Buyer Information

This section outlines pertinent details about the entity or individual placing the purchase order. It includes the buyer’s name, address, contact information, and any department or division responsible for the purchase.

- Order Date and Delivery Date

The order date indicates when the purchase order is issued, serving as a reference point for tracking order timelines and fulfillment. The delivery date specifies the agreed-upon or expected date for the delivery of goods or completion of services.

- Item Description

Detailed descriptions of the items or services being purchased are essential for clarity and accuracy in the procurement process. This section typically includes item names, descriptions, quantities, unit prices, and relevant specifications or part numbers.

- Pricing and Total Value

The pricing section of a purchase order outlines the transaction’s financial terms, including the unit price of each item, any applicable taxes or fees, and the total value of the order. Additionally, it may include details about shipping costs, discounts, or other charges relevant to the purchase.

- Delivery Location

Specifying the delivery location ensures that goods are delivered to the correct address or destination. This information may include the physical address, building or room number, or any other relevant location details necessary for successful delivery.

- Payment Terms

Payment terms outline the agreed-upon payment conditions, including payment method, due dates, and applicable discounts or penalties. Common payment terms may include net payment terms (e.g., net 30 days), milestones, or upfront payment requirements.

- Authorization Signatures

Authorization signatures represent formal approval and acceptance of the purchase order terms and conditions by authorized personnel from both the buyer and the vendor. These signatures confirm mutual agreement on the terms of the transaction and serve as a legally binding acknowledgment of the purchase order’s validity.

- Terms and Conditions

A purchase order’s terms and conditions section includes legal and contractual provisions governing the transaction. This may encompass warranties, return policies, liability clauses, dispute resolution mechanisms, and any other relevant terms agreed upon by the buyer and the vendor.

The Lifecycle of a Purchase Order in Logistics

- Purchase Requisition: This is the initial stage where a need for goods or services is identified within the organization. A purchase requisition is raised to request the purchase formally.

- Purchase Order Creation: A purchase order (PO) is created once the purchase requisition is approved. The PO includes details such as the quantity, description, price, and terms of the goods or services to be purchased.

- Approval Process: The PO typically goes through an approval process, which is reviewed and approved by relevant organizational stakeholders. This ensures that the purchase is authorized and within budget.

- Vendor Selection and Confirmation: After the PO is approved, the next step is to select a vendor who can fulfill the order. This may involve requesting quotes, negotiating terms, and confirming the vendor.

- Order Fulfillment: Once the vendor is confirmed, they fulfill the order. This involves sourcing, packaging, and preparing the goods for shipment.

- Delivery and Inspection: The goods are delivered to the specified location. Upon receipt, they are inspected to ensure they meet the quality and quantity specified in the PO.

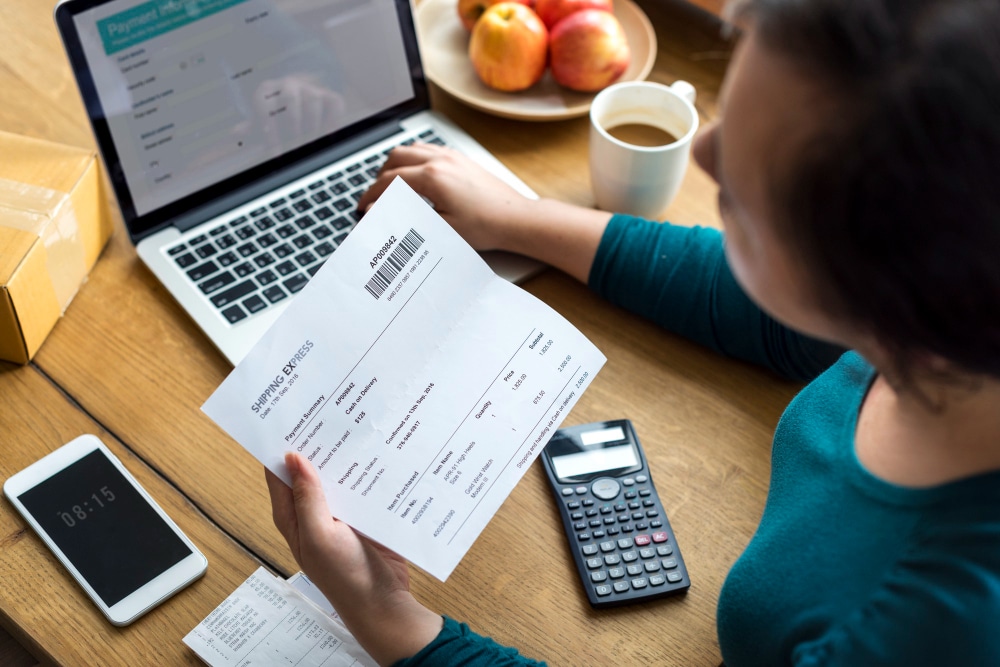

- Invoice Reconciliation: Once the goods are accepted, the vendor sends an invoice to the buyer for payment. The invoice is reconciled with the original PO to ensure accuracy.

- Payment Processing: After reconciling the invoice, the buyer processes the payment to the vendor based on the agreed-upon terms. This may involve issuing a check, initiating a bank transfer, or using electronic payment methods.

- Record Keeping: All documents related to the purchase order, including the PO, invoice, and payment records, are meticulously recorded and stored for future reference and auditing purposes.

- Closeout: The purchase order is closed once all steps have been completed satisfactorily. This involves updating records, archiving documents, and resolving any outstanding issues.

Common Formats of Purchase Orders

Standard Purchase Order (SPO)

A Standard Purchase Order (SPO) is the most commonly used purchase order type in business transactions. It serves as a formal request from a buyer to a seller to procure goods or services.

SPOs typically include item descriptions, quantities, prices, delivery dates, payment terms, and other relevant terms and conditions.

Planned Purchase Order (PPO)

Planned Purchase Orders (PPOs) are utilized when there is a long-term agreement between the buyer and the seller to purchase goods or services over an extended period.

These agreements outline the terms and conditions for future transactions, including pricing, quantities, delivery schedules, and quality standards.

Blanket Purchase Order (BPO)

A Blanket Purchase Order (BPO) is similar to a PPO but typically covers a shorter period, such as a month or a quarter.

It is used when the buyer has a recurring need for goods or services from a specific supplier but does not want to create individual purchase orders for each transaction.

Contract Purchase Order (CPO)

Contract Purchase Orders (CPOs) are issued against formal contracts or agreements between the buyer and the seller.

These contracts outline the terms and conditions governing the entire procurement relationship, including pricing, delivery schedules, payment terms, quality standards, warranties, and dispute resolution mechanisms.

Electronic Purchase Order (EPO)

An Electronic Purchase Order (EPO) is any purchase order transmitted and processed electronically, typically using electronic data interchange (EDI) systems or procurement software.

EPOs can be any of the purchase orders but leverage technology to streamline the procurement process, improve efficiency, and reduce errors.

5 Best Practices for Managing Purchase Orders in Logistics

- Automate the Process: Implementing automated systems for generating, processing, and tracking purchase orders can significantly reduce errors, streamline operations, and enhance efficiency.

- Standardize Procedures: Establishing standardized procedures ensures consistency and reduces the likelihood of errors or misunderstandings in the purchase order process. This includes defining clear protocols for creating, approving, and processing purchase orders and specifying roles and responsibilities within the procurement workflow.

- Maintain Accurate Data: Accurate and up-to-date data is crucial for effective purchase order management. This includes maintaining accurate product catalogs, pricing information, vendor details, and inventory levels.

- Establish Good Relationships with Suppliers: Building strong relationships with suppliers fosters collaboration, trust, and reliability in procurement. Effective communication, transparent negotiations, and timely payments are essential for cultivating positive vendor relationships.

- Regularly Review and Analyze Orders: Reviewing and analyzing purchase orders helps identify trends, optimize purchasing decisions, and identify opportunities for cost savings or process improvements.

Conclusion

Purchase orders play a central role in procurement, serving as a formal agreement between buyers and sellers to purchase goods or services.

Understanding the key components, lifecycle stages, common formats, and best practices for managing purchase orders is essential for optimizing procurement processes, reducing costs, and maintaining strong supplier relationships.

By implementing efficient procurement practices and leveraging technology, organizations can streamline their purchasing operations and achieve greater efficiency and transparency in their supply chain management.

| Fulfill Orders with High Efficiency Achieve high efficiency in order fulfillment by optimizing purchase order processes with Detrack. Create an Account Today |