Summary

- Construction logistics is the coordination of materials, equipment, and deliveries

- For suppliers, it’s about getting the right materials to the right site at the right time, with clear communication every step of the way

- Poor logistics costs the construction industry billions each year in deliveries that fail and delay projects

- Whether you’re delivering concrete, roofing materials, timber, plumbing supplies, or heavy machinery, timing, communication, and reliability are mission critical

- Suppliers who understand construction logistics become the ones sites want to work with

Construction projects are complex – from coordinating deliveries to busy job sites, limited access windows, multiple stakeholders, and tight deadlines that cannot be missed.

Here we’ll break down what construction logistics means for everyone involved, and why getting it right is critical for suppliers, contractors, and project managers alike, especially in an industry where every delay has a ripple effect.

What is construction logistics?

Construction logistics is the planning, coordination, and execution of deliveries to and from construction sites, including materials, equipment, tools, and waste removal.

For construction sites, logistics means managing dozens of deliveries from different suppliers, making sure materials arrive when they’re needed, knowing when goods will be on site, and keeping the project on schedule.

For suppliers, logistics means understanding how construction sites operate in order to deliver reliably, communicate clearly, and help customers avoid delays and disruption. Unlike warehouses or retail locations, construction sites present unique challenges:

- No fixed loading docks or reception points

- Inaccurate or changing site addresses and access points

- Tight delivery windows with limited storage space

- Multiple trades and suppliers competing for access

- Different people ordering, receiving, and managing deliveries

- Use delivery data for accurate back costing and job profitability analysis

- Site managers typically not on site at time of delivery

Understanding these challenges ensures that your building and construction customers are served well, and want to keep working with you.

Who needs to get construction logistics right?

Construction logistics isn’t just a concern for the biggest suppliers or the largest projects. Anyone delivering to construction sites needs to understand how these environments work.

Whatever you’re supplying, the fundamentals are the same: know when your customer needs the delivery, communicate clearly, show up when you say you will, and have proof that you did.

If unloading equipment isn’t ready when the truck arrives, everyone waits. Knowing what’s available on site is critical.

| Industry | Why they need it |

| Roofing materials | Weather-dependent projects with tight schedules. Materials often need to arrive the morning of installation—delays leave crews waiting, early arrivals mean materials sitting exposed. |

| Steel and structural materials | Heavy, high-value deliveries require coordination with site equipment and careful placement. Photo proof of delivery protects both supplier and customer. |

| Mechanical trade supplies (plumbing, electrical, HVAC) | These trades work tight schedules between other contractors. Late materials mean they’ve moved to another job. Unannounced arrivals mean no one to receive them. Reliable delivery windows let them plan their day. |

| Windows and doors | High-value items needing careful handling and specific unloading arrangements. Photo proof of delivery is important for damage claims. |

| Fixtures, fittings, and finishing materials | Bathroom fixtures, kitchen units, flooring, paint. Often delivered closer to project completion when sites are busiest. Coordination helps avoid congestion, and secure handover with clear proof of delivery matters for high-value items. |

| Heavy machinery, plant, and equipment hire | Excavators, cranes, scaffolding, tools. High-value equipment needing confirmed site access and clear handover. Late delivery stops entire trades—scaffolding delays mean no work at height, missing tools mean jobs don’t get done. |

| Skip hire and waste removal | Skips need to arrive before waste accumulates and be collected before they overflow or block access. |

Why construction logistics matters

Poor logistics have a real cost. Construction workers lose almost two full working days each week solving avoidable issues and searching for project information (FMI/PlanGrid 2018). Nearly 75% of construction businesses say they spend less than half their time doing actual construction work (Levelset 2020).

Over the past two decades, construction productivity has grown at just 1% per year, far behind manufacturing (3.6%) and the average across all industries (2.8%). If construction closed this gap, the industry could unlock an estimated $1.6 trillion in additional value annually (McKinsey).

For suppliers, poor logistics means:

- Failed deliveries when no one’s there to receive

- Wasted trips, fuel, and driver time

- Rescheduling and frustrated customers

- Damaged relationships and lost repeat business

- Reduced margins

For construction sites, poor logistics means wasted time and money:

- Crews standing idle waiting for materials

- Equipment hired for the day sitting unused

- Trades scheduled for later getting pushed back

- Project timelines slipping, affecting handovers and payments

- For time-sensitive materials, entire loads wasted

The takeaway: when construction logistics aren’t optimal, everyone pays for it. When it works, cost and time savings are gained, and relationships are strengthened.

What often goes wrong and how to get it right

Most construction delivery failures fall into predictable scenarios. Understanding them makes them easier to prevent.

Timing and scheduling

The challenge: “No one was there.” The site didn’t know when to expect the truck, the site manager wasn’t available, or the driver arrived outside the expected window. Later, the delivery window is missed and the delivery arrives when the site has moved on to other tasks.

Getting it right: Clear ETA notifications to multiple contacts, live tracking, and immediate delay alerts. Materials need to arrive when teams are ready, not before (nowhere to store them) and not after (crews standing idle or gone).

Site access

The challenge: The driver goes to the wrong gate, or access arrangements have changed since the order was placed.

Getting it right: Confirm access points, compliance and security requirements, and unloading areas before dispatch. These change as projects progress.

Equipment coordination

The challenge: The truck arrives but the forklift is across the site or the crane is mid-lift. Everyone waits.

Getting it right: Communicate exact arrival times so unloading equipment can be scheduled.

Real-time communication

The challenge: The site needs to reschedule but the truck is already en route, or information sits with one person when three people need it.

Getting it right: SMS and WhatsApp notifications, live tracking, and real-time updates solve problems that phone calls and emails can’t. Multiple people often need the same information at the same time.

Flexibility

The challenge: Construction projects change constantly due to weather, other trades, site conditions, or client decisions.

Getting it right: Suppliers who can adapt quickly become valuable partners.

Proof of delivery

The challenge: “We only received half the order.” “The materials were damaged.” Or materials get dropped in the wrong spot because no one was there to direct the driver.

Getting it right: Photos, GPS locations, timestamps, and digital signatures provide clear records that protect everyone and resolve disputes quickly.

The right technology is everything

As projects become more complex and sites busier, spreadsheets, phone calls, and best guesses are a blocker to proving an excellent customer experience, and scaling your business for growth. This is where delivery management technology is everything.

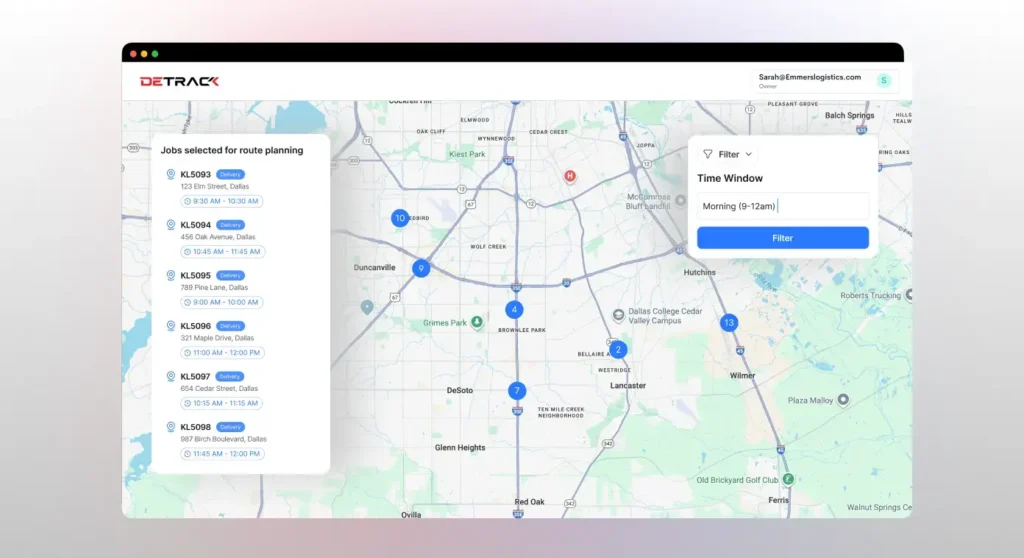

Route optimisation

Many building and construction suppliers are delivering to multiple sites per day. Managing sequences, optimising routes, and keeping multiple customers informed requires systems that can handle complexity. Plus, when things change throughout the day, the right tools enable you to reoptimise in just a few clicks, and without throwing off the rest of your schedule.

Live tracking

Give your customers visibility of where the driver is without them having to call and ask. This reduces “where’s my delivery?” calls, and helps sites prepare for arrivals. It also ensures your support and office teams are less reactive and are freed up to spend their time more efficiently.

SMS and WhatsApp notifications

The communication channel that actually reaches people on construction sites. Email doesn’t get checked. Apps add friction. SMS lands on the phone in their pocket. The right platform enables you to send dispatch confirmations, live ETAs, delay alerts, and delivery confirmations to multiple recipients.

Electronic proof of delivery

Everything is instantly available and stored securely for future reference – photos showing where materials were left and their condition, GPS confirming the delivery happened at the right site, timestamps proving when delivery was made, and signatures capturing who received it.

The difference between a supplier and a preferred supplier

The suppliers construction sites actually want to work with are those that they can rely on and don’t need to chase up. The most successful preferred suppliers are consistent in:

- Confirming details before dispatch so that there are no surprises

- Keeping the site informed with live tracking and SMS updates

- Showing up when they say they will, or communicate immediately when they can’t

- Make handoffs seamless

- Providing clear, digital proof of every delivery

- Being easy to work with, especially when things change

This is how you move from “one of the suppliers” to “the supplier we call first.”

Conclusion

Construction logistics is about getting the right materials to the right site at the right time, with clear communication at every step.

When logistics fail, crews wait, deliveries get missed, and project schedules slip. For suppliers, this means wasted trips and frustrated customers. For construction sites, it means lost productivity and rising costs.

Suppliers who get logistics right become trusted partners. Route optimisation, live tracking, SMS notifications, and electronic proof of delivery aren’t optional extras — they’re the tools that make reliable delivery possible.

The fundamentals are the same whether you’re delivering concrete, timber, roofing materials, or hire equipment: timing, communication, proof of delivery, and the flexibility to adapt when things change.

Frequently asked questions

What is construction logistics?

Construction logistics is the planning and coordination of materials, equipment, and goods moving to and from construction sites. It ensures deliveries arrive at the right place, at the right time, and in the right sequence so work can continue without delays or disruption to crews.

Why is logistics important in construction?

Logistics directly affects productivity, project timelines, and costs. Poor logistics leads to idle crews, missed deliveries, wasted materials, and schedule delays. Effective logistics keeps projects on track, helps sites stay productive and on budget, and builds trust between suppliers and construction teams.

What are the main challenges of delivering to construction sites?

Construction sites often have no loading docks, changing access points, limited storage, and tight delivery windows. The person receiving materials may not be the one who ordered them. Without clear communication, deliveries can fail due to missed timing, wrong access points, or unavailable unloading equipment.

How can suppliers improve their construction deliveries?

Suppliers can improve delivery success by confirming site details before dispatch, sharing clear ETAs via SMS or WhatsApp, providing live tracking, and capturing electronic proof of delivery. Being flexible with changing schedules and understanding site constraints also helps suppliers become reliable partners rather than just vendors.

Why is communication so important for construction logistics?

Most construction communication happens on-site and on mobile devices. Without timely updates about arrivals or delays, crews can’t prepare unloading areas or schedule trades efficiently. Clear communication reduces failed deliveries, idle time, and stress, keeping projects moving smoothly and everyone on the same page.

What should proof of delivery include for construction materials?

Proof of delivery should include delivery time and date, GPS location, photos showing materials and placement, and the recipient’s name or signature. This provides clear records to resolve disputes, confirm accurate delivery, protect suppliers, and ensure construction sites know exactly what was delivered and when.

What types of suppliers need to understand construction logistics?

Any supplier delivering to construction sites should understand construction logistics. This includes concrete, timber, steel, roofing, plumbing, electrical, HVAC, equipment hire, scaffolding, aggregates, and builders’ merchants. The fundamentals remain the same: timing, communication, access, and reliable delivery.

How does technology help with construction logistics?

Technology makes logistics manageable with route optimisation, live tracking, SMS/WhatsApp notifications, electronic proof of delivery, and multi-drop management. Tools like Detrack reduce failed deliveries, keep customers informed, and allow suppliers and sites to coordinate efficiently, saving time, costs, and frustration.

What software is used for construction logistics?

Delivery management platforms like Detrack are widely used to streamline construction logistics. They handle route optimisation, live tracking, automated SMS notifications, and electronic proof of delivery. Using software helps suppliers hit delivery windows, communicate clearly, and provide transparency for busy construction sites.